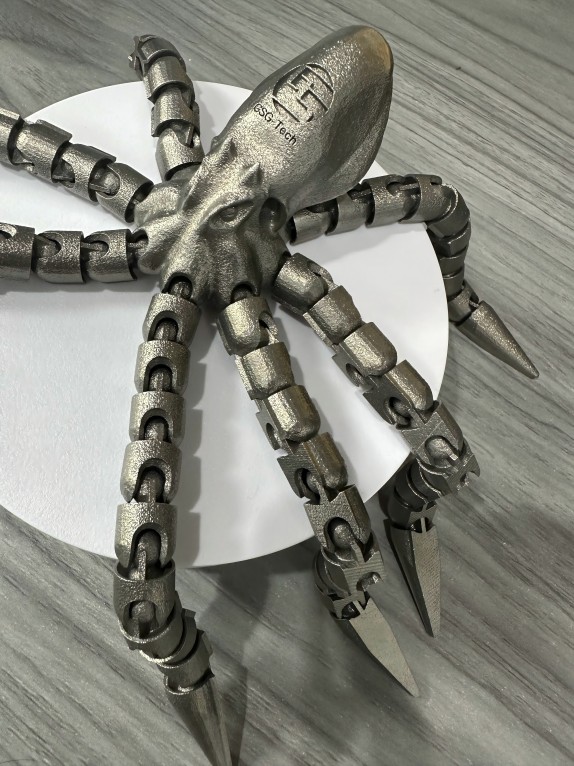

I kēia mau lā, ua hana mākou i kahi hōʻikeʻike metalaPaʻi 3D, a ua hoʻopau maikaʻi mākou, no laila he aha ka metalaPaʻi 3D? He aha nā mea maikaʻi a me nā pōʻino?

ʻO ka paʻi metala 3D kahi ʻenehana hana hoʻohui e kūkulu i nā mea ʻekolu-dimensional ma o ka hoʻohui ʻana i nā mea metala ʻāpana ma ka papa. Eia kahi hoʻolauna kikoʻī i ka paʻi 3D metala:

Kuʻuna loea

Selective laser sintering (SLS): ʻO ka hoʻohana ʻana i nā kukuna laser ikehu kiʻekiʻe e hoʻoheheʻe koho a hoʻoheheʻe ʻia nā pauka metala, e hoʻomehana ana i ka mea pauka i kahi mahana ma lalo iki o kona wahi hoʻoheheʻe, i hoʻokumu ʻia ai nā paʻa metallurgical ma waena o nā ʻāpana pauda, a laila kūkulu ʻia ka papa ma ka papa. I ke kaʻina hana paʻi, kau mua ʻia kahi ʻāpana like ʻole o ka pauka metala ma luna o ke kahua paʻi, a laila nānā ka laser beam i ka pauka e like me ke ʻano o ke ʻano o ka ʻāpana o ka mea, i hoʻoheheʻe ʻia ka pauka scanned a paʻa pū, ma hope o ka pau ʻana o kahi papa o ka paʻi ʻana, hāʻule ka paepae i kahi mamao, a laila hohola i kahi papa hou o ka pauka, e hana hou i ke kaʻina hana ma luna a hiki i ka paʻi ʻana o ka mea holoʻokoʻa.

Selective Laser Melting (SLM): E like me ka SLS, akā me ka ikaika laser kiʻekiʻe, hiki ke hoʻoheheʻe ʻia ka pauka metala e hana i kahi ʻano ʻoi aku ka nui, hiki ke loaʻa ke kiʻekiʻe kiʻekiʻe a ʻoi aku ka maikaʻi o nā waiwai mechanical, a ʻoi aku ka ikaika a me ka pololei o nā ʻāpana metala i paʻi ʻia. He kūpono ia no ka hana ʻana i nā ʻāpana i ka aerospace, nā lāʻau lapaʻau a me nā māla ʻē aʻe e koi ai i ka pololei kiʻekiʻe a me ka hana.

Electron beam melting (EBM): Ka hoʻohana ʻana i nā kukuna electron ma ke ʻano he kumu ikehu e hoʻoheheʻe ai i nā pauka metala. Loaʻa i ka electron beam nā hiʻohiʻona o ka ikehu kiʻekiʻe a me ka wikiwiki scanning kiʻekiʻe, hiki ke hoʻoheheʻe koke i ka pauka metala a hoʻomaikaʻi i ka hana paʻi. ʻO ka paʻiʻana i loko o kahi'eneʻeneʻa hiki ke pale i ka hopena o nā mea metala me ka oxygen i ka wā o ka paʻiʻana, kahi kūpono no ka paʻiʻana i ka titanium alloy, nickel-based alloy a me nā mea metala'ē aʻe e pili ana i ka oxygen content, i hoʻohana pinepineʻia i ka aerospace, nā mea lapaʻau a me nā kula kiʻekiʻe.

Metal extrusion (ME): Material extrusion ma muli o ka hana hana, ma o ke poʻo extrusion e hoʻokuʻu i ka mea metala ma ke ʻano o ka siliki a i ʻole ka paʻi, a i ka manawa like e wela a hoʻōla, i mea e hoʻokō ai i ka papa ma ka ʻāpana hoʻohuihui. Hoʻohālikelike ʻia me ka ʻenehana hoʻoheheʻe laser, ʻoi aku ka haʻahaʻa o ke kumukūʻai hoʻopukapuka, ʻoi aku ka maʻalahi a me ka maʻalahi, ʻoi aku ka kūpono no ka hoʻomohala mua ʻana i ke keʻena o ke keʻena a me ka ʻoihana.

Mea maʻamau

Titanium alloy: loaʻa nā mea maikaʻi o ka ikaika kiʻekiʻe, haʻahaʻa haʻahaʻa, kūpaʻa maikaʻi i ka corrosion a me ka biocompatibility, hoʻohana nui ʻia i ka aerospace, nā lāʻau lapaʻau, nā kaʻa a me nā ʻano ʻē aʻe, e like me nā mīkini mokulele mokulele, nā hui a me nā ʻāpana hana ʻē aʻe.

ʻO ke kila kila: maikaʻi ke kū'ēʻana i ka corrosion, mechanical properties a me ka hoʻoponoponoʻana i nā waiwai, ke kumu kūʻai haʻahaʻa,ʻo ia kekahi o nā mea i hoʻohana mauʻia i ka paʻi 3D metala, hiki ke hoʻohanaʻia no ka hanaʻana i nāʻano mechanical, nā mea hana, nā mea lapaʻau a pēlā aku.

Aluminum Aluminum: haʻahaʻa haʻahaʻa, ikaika kiʻekiʻe, conductivity thermal maikaʻi, kūpono no ka hana ʻana i nā ʻāpana me nā koi kaumaha kiʻekiʻe, e like me ka pahu pahu pahu kaʻa, nā ʻāpana aerospace, etc.

Nickel-based alloy: me ka ikaika kiʻekiʻe kiʻekiʻe o ka wela, ka pale ʻana i ka corrosion a me ka pale ʻana i ka oxidation, hoʻohana pinepine ʻia i ka hana ʻana i nā mea wela kiʻekiʻe e like me nā mokulele mokulele a me nā turbines kinoea.

pono

ʻO ke kūlana kiʻekiʻe o ke kūʻokoʻa hoʻolālā: ʻO ka hiki ke hoʻokō i ka hana ʻana i nā ʻano paʻakikī a me nā hale, e like me nā hale lattice, topologically optimized structures, etc.

E ho'ēmi i ka helu o nā'āpana: hiki ke hoʻohuiʻia nā'āpana he nui i kahi holoʻokoʻa, e ho'ēmi i ka pilina a me ke kaʻina hana ma waena o nā'āpana, e hoʻonui i ka pono hana, e ho'ēmi i nā kumukūʻai, akā e hoʻonui i ka hilinaʻi a me ka paʻa o ka huahana.

Hoʻopuka wikiwiki: Hiki iā ia ke hana i kahi prototype o kahi huahana i ka manawa pōkole, wikiwiki i ka pōʻai hoʻomohala huahana, hōʻemi i nā kumukūʻai noiʻi a me ka hoʻomohala ʻana, a kōkua i nā ʻoihana e lawe i nā huahana i ka mākeke wikiwiki.

ʻO ka hana maʻamau: E like me nā pono pilikino o nā mea kūʻai aku, hiki ke hanaʻia nā huahana kūikawā no ka hoʻokōʻana i nā koi kūikawā o nā mea kūʻai likeʻole, kūpono no nā lāʻau lapaʻau, nā mea nani a me nā māla'ē aʻe.

Ka palena

ʻO ka maikaʻi o ka ʻili maikaʻi: ʻoi aku ka kiʻekiʻe o ka ʻili o nā ʻāpana metala i paʻi ʻia, a koi ʻia ka mālama ʻana ma hope, e like me ka wili, polishing, sandblasting, a me nā mea ʻē aʻe, e hoʻomaikaʻi i ka hoʻopau ʻana o ka ʻili, hoʻonui i ke kumukūʻai hana a me ka manawa.

Nā hemahema o loko: aia paha nā hemahema o loko e like me nā pores, unfused particles, a me ka hui piha ʻole i ka wā o ke kaʻina paʻi, e pili ana i nā waiwai mechanical o nā ʻāpana, ʻoi aku hoʻi i ka hoʻohana ʻana i ka ukana kiʻekiʻe a me ka ukana cyclic, pono e hōʻemi i ka hiki ʻana o nā hemahema o loko ma o ka hoʻonui ʻana i nā ʻāpana kaʻina paʻi a me ka hoʻohana ʻana i nā ʻano hana post-processing kūpono.

Nā palena waiwai: ʻOiai ke hoʻonui nei nā ʻano mea paʻi metala 3D i loaʻa, aia nō kekahi mau palena waiwai i hoʻohālikelike ʻia me nā ʻano hana kuʻuna, a ʻoi aku ka paʻakikī o kekahi mau mea metala hana kiʻekiʻe ke paʻi a ʻoi aku ke kumukūʻai.

Nā kumu kūʻai: He kiʻekiʻe ke kumukūʻai o nā mea paʻi 3D metala a me ka wikiwiki o ka paʻi ʻana, ʻaʻole ia e like me ke kumu kūʻai e like me nā kaʻina hana kuʻuna no ka hana nui, a i kēia manawa kūpono no ka liʻiliʻi liʻiliʻi, hana maʻamau a me nā wahi me ka hana kiʻekiʻe o ka huahana a me nā koi kūpono.

Paʻakikī ʻenehana: ʻO ka paʻi ʻana metala 3D e pili ana i nā ʻāpana kaʻina hana paʻakikī a me ka mana kaʻina hana, e koi ana i nā mea hoʻohana ʻoihana a me ke kākoʻo ʻenehana, a koi i ka pae ʻenehana kiʻekiʻe a me ka ʻike o nā mea hana.

Kahua noi

Aerospace: Hoʻohana ʻia e hana i nā ʻāpana aero-engine, nā turbine disc, nā ʻēheu, nā ʻāpana satellite, a me nā mea ʻē aʻe, hiki ke hōʻemi i ke kaumaha o nā ʻāpana, hoʻomaikaʻi i ka wahie, hoʻemi i nā kumukūʻai hana, a hōʻoia i ka hana kiʻekiʻe a me ka hilinaʻi o nā ʻāpana.

Kaʻa: Hana i ka pahu pahu pahu kaʻa, ka pūpū hoʻouna, nā ʻāpana hana māmā, a me nā mea ʻē aʻe, e hoʻokō i ka hoʻolālā māmā o nā kaʻa, hoʻomaikaʻi i ka hoʻokele waiwai a me ka hana.

Lapaʻau: ʻO ka hana ʻana o nā lāʻau lapaʻau, nā hui artificial, orthotics niho, nā mea lapaʻau implantable, a me nā mea ʻē aʻe, e like me nā ʻokoʻa pilikino o nā mea maʻi i hana ʻia, hoʻomaikaʻi i ke kūpono o nā lāʻau lapaʻau a me nā hopena lapaʻau.

ʻO ka hana ʻana: ʻO ka hana ʻana i nā mold injection, nā mea hoʻoheheʻe make, a me nā mea ʻē aʻe, e hoʻopōkole i ka pōʻaiapili hana ʻana, e hoʻemi i nā kumukūʻai, e hoʻomaikaʻi i ka pololei a me ka paʻakikī o ka mold.

Electronics: Hana i nā radiators, nā pūpū, nā papa kaapuni o nā lako uila, a me nā mea ʻē aʻe, e hoʻokō i ka hana hoʻohui ʻia o nā hale paʻakikī, hoʻomaikaʻi i ka hana a me ka hopena wela o nā mea uila.

Nā mea nani: E like me ka mea hoʻolālā a me nā pono o ka mea kūʻai aku, hiki ke hana ʻia nā ʻano mea kūʻai like ʻole e hoʻomaikaʻi ai i ka hana pono a me ka pilikino huahana.

Ka manawa hoʻouna: Nov-22-2024